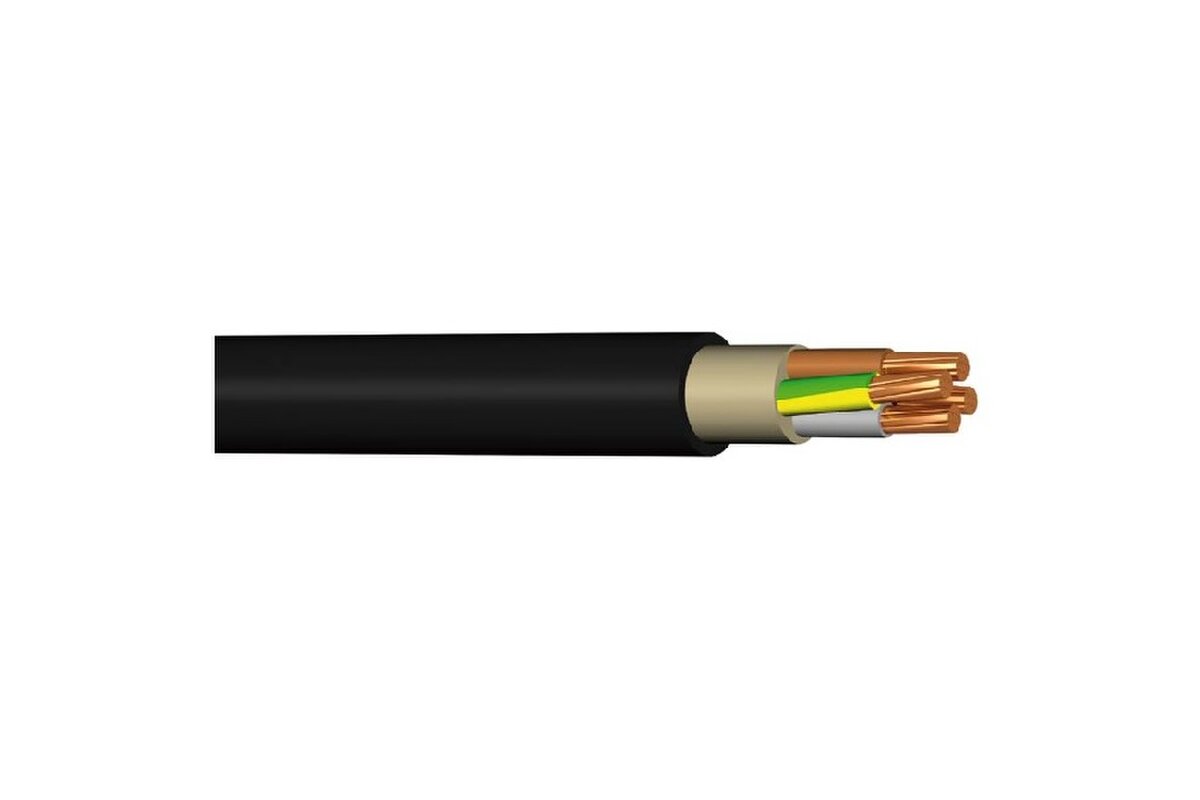

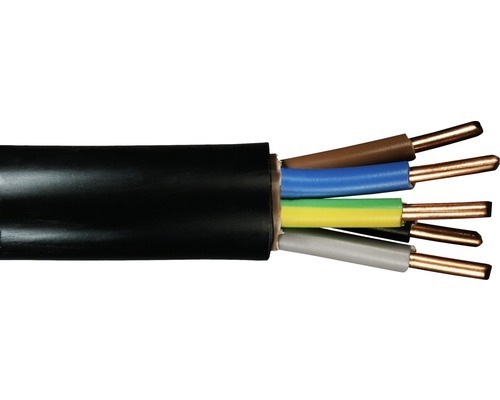

NYY-J / NYY-O, 0.6/1KV, 70º C

Application

NYY power cable is designed for energy supply in cable ducts, power stations, industry and distribution boards and in subscriber networks. May also be used in brickwork and in concrete with the exception of cabling in shaken, vibrated or compressed concrete. NYY cables can be installed in open air, underground,in water and indoors where mechanical damages are not to be expected. The UV-resistance allows for outdoor use.

Standard

DIN VDE-0276-603 & 627, HD 603 & 607.S1

Construction

Conductor: Solid or stranded, plain copper conductor to DIN VDE 0295 class 1 or class 2, and IEC 60228 class 1 or class 2

Conductor form:

RE: round, solid

RM: round, stranded

SE: sector shaped, solid

SM: sector shaped, stranded

Insulation: PVC insulation

Color coded to DIN VDE 0293-308, 0276 part 603 or HD 186

Conductor color for 3+1/2 conductor

J-type: green-yellow (1/2), brown, black, gray (with green/yellow core)

O-type: blue (1/2), brown, black, gray (without green/yellow core)

Sheath: PVC outer jacket

Technical Characteristics

Rated voltage: 0.6/1KV

Test voltage: 4000 volts

Flexing bending radius: 15 x Ø

Static bending radius: 12 x Ø

Operating temperature: 70º C

Flame retardant: IEC 60332.1

Technical Parameter

NYY

| Nominal Cross Sectional Area | No. of wires | Wire Dia. | Nom. PVC Insulation Thickness | Min. PVC Insulation Thickness | Nom. PVC Sheath Thickness | Overall Diameter | Maximum Resistance of Conductor at 20°C | |

| Min. OD | Max. OD | Plain Copper Wires | ||||||

| mm² | mm | mm | mm | mm | mm | mm | Ω/km | |

| 1 x 10 RE | 1 | 3.57 | 1.0 | 0.80 | 1.8 | 10.0 | 12.0 | 1.83 |

| 1 x 16 RE | 1 | 4.51 | 1.0 | 0.80 | 1.8 | 11.0 | 13.0 | 1.15 |

| 1 x 25 RM | 7 | 2.13 | 1.2 | 0.98 | 1.8 | 12.0 | 15.0 | 0.727 |

| 1 x 35 RM | 7 | 2.52 | 1.2 | 0.98 | 1.8 | 13.0 | 16.0 | 0.524 |

| 1 x 50 RM | 19 | 1.83 | 1.4 | 1.16 | 1.8 | 15.0 | 18.0 | 0.387 |

| 1 x 70 RM | 19 | 2.17 | 1.4 | 1.16 | 1.8 | 16.0 | 19.0 | 0.268 |

| 1 x 95 RM | 19 | 2.52 | 1.6 | 1.34 | 1.8 | 18.0 | 21.0 | 0.193 |

| 1 x 120 RM | 37 | 2.03 | 1.6 | 1.34 | 1.8 | 20.0 | 23.0 | 0.153 |

| 1 x 150 RM | 37 | 2.27 | 1.8 | 1.52 | 1.8 | 22.0 | 26.0 | 0.124 |

| 1 x 185 RM | 37 | 2.52 | 2.0 | 1.70 | 1.8 | 24.0 | 28.0 | 0.0991 |

| 1 x 240 RM | 61 | 2.24 | 2.2 | 1.88 | 1.8 | 27.0 | 31.0 | 0.0754 |

| 1 x 300 RM | 61 | 2.50 | 2.4 | 2.06 | 1.9 | 29.0 | 33.0 | 0.0601 |

| 1 x 400 RM | 61 | 2.89 | 2.6 | 2.24 | 2.0 | 33.0 | 38.0 | 0.0470 |

| 1 x 500 RM | 61 | 3.23 | 2.8 | 2.42 | 2.1 | 37.0 | 42.0 | 0.0366 |

NYY-O & NYY-J

| Nominal Cross Sectional Area | No. of wires | Wire Dia. | Nom. PVC Insulation Thickness | Min. PVC Insulation Thickness | Nom. PVC Sheath Thickness | Overall Diameter | Maximum Resistance of Conductor at 20°C | |

| Min. OD | Max. OD | Plain Copper Wires | ||||||

| mm² | mm | mm | mm | mm | mm | mm | Ω/km | |

| 3 x 16 RE | 1 | 4.51 | 1.0 | 0.80 | 1.8 | 19.0 | 22.0 | 1.15 |

| 4 x 4 RE | 1 | 2.25 | 1.0 | 0.80 | 1.8 | 14.0 | 19.0 | 4.61 |

| 4 x 6 RE | 1 | 2.76 | 1.0 | 0.80 | 1.8 | 17.0 | 21.0 | 3.08 |

| 4 x 10 RE | 1 | 3.57 | 1.0 | 0.80 | 1.8 | 20.0 | 24.0 | 1.83 |

| 4 x 16 RE | 1 | 4.51 | 1.0 | 0.80 | 1.8 | 24.0 | 30.0 | 1.15 |

| 3 x 25 RM/ 16 RE | 7 | 2.13 | 1.2/1.0 | 0.98/0.80 | 1.8 | 24.0 | 30.0 | 0.727 |

| 3 x 35 SM/ 16 RE | 7 | 2.52 | 1.2/1.0 | 0.98/0.80 | 1.8 | 24.0 | 31.0 | 0.524 |

| 3 x 50 SM/ 25 RM | 19 | 1.83 | 1.4/1.2 | 1.16/0.98 | 1.9 | 28.0 | 35.0 | 0.387 |

| 3 x 70 SM/ 35 SM | 19 | 2.17 | 1.4/1.2 | 1.16/0.98 | 2.0 | 31.0 | 38.0 | 0.268 |

| 3 x 95 SM/ 50 SM | 19 | 2.52 | 1.6/1.4 | 1.34/1.16 | 2.2 | 37.0 | 44.0 | 0.193 |

| 3 x 120 SM/ 70 SM | 37 | 2.03 | 1.6/1.4 | 1.34/1.16 | 2.3 | 40.0 | 48.0 | 0.153 |

| 3 x 150 SM/ 70 SM | 37 | 2.27 | 1.8/1.4 | 1.52/1.16 | 2.4 | 44.0 | 52.0 | 0.124 |

| 3 x 185 SM/ 95 SM | 37 | 2.52 | 2.0/1.6 | 1.70/1.34 | 2.6 | 49.0 | 57.0 | 0.0991 |

| 3 x 240 SM/ 120 SM | 61 | 2.24 | 2.2/1.6 | 1.88/1.34 | 2.8 | 56.0 | 64.0 | 0.0754 |

| 5 x 4 RE | 1 | 2.25 | 1.0 | 0.80 | 1.8 | 15.0 | 18.0 | 4.61 |

| 5 x 6 RE | 1 | 2.76 | 1.0 | 0.80 | 1.8 | 17.0 | 20.0 | 3.08 |

| 7 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 17.0 | 12.1 |

| 10 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 21.0 | 12.1 |

| 12 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 21.0 | 12.1 |

| 14 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 22.0 | 12.1 |

| 19 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 25.0 | 12.1 |

| 24 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 28.0 | 12.1 |

| 30 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 29.0 | 12.1 |

| 40 x 1.5 RE | 1 | 1.38 | 0.8 | 0.62 | 1.8 | – | 33.0 | 12.1 |

| 7 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 18.0 | 7.41 |

| 10 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 22.0 | 7.41 |

| 12 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 23.0 | 7.41 |

| 14 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 24.0 | 7.41 |

| 19 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 27.0 | 7.41 |

| 24 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 30.0 | 7.41 |

| 30 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 32.0 | 7.41 |

| 40 x 2.5 RE | 1 | 1.78 | 0.8 | 0.62 | 1.8 | – | 36.0 | 7.41 |