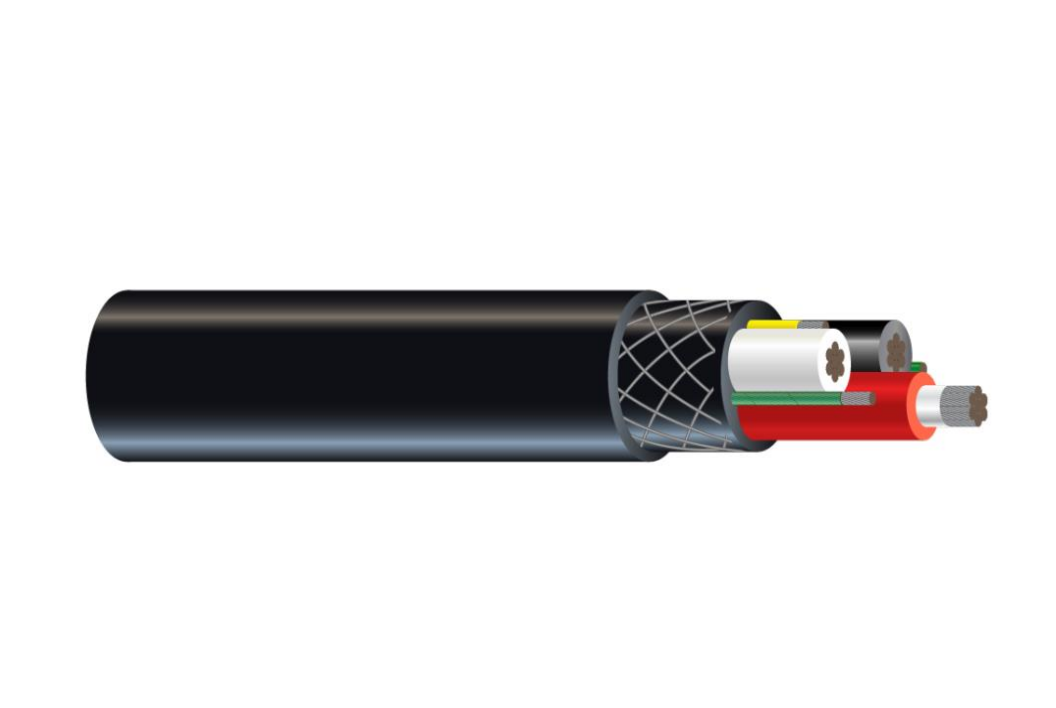

Application

Type G-GC cable is a heavy-duty cable for use where flexibility and maximum protection is required. For use with all portable, temporary, and permanent power applications such as mobile or stationary mining equipment, shuttle cars, mobile drills, pumps, roof bolters, conveyors, and any portable power where equipment grounding is required.

Temperature rating and voltage rating

90°C and 2000V

Standard References

ASTM B3 Specification for Soft or Annealed Copper Wire

ASTM B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

ASTM B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Copper Conductors

ANSI/NEMA WC 58/ICEA S-75-381: Portable and Power Feeder Cables for Use in Mines and Similar Applications

UL1650: Portable Power Cable

CSA-C22.2 No.96: Portable Power Cables

MSHA : Mine Safety & Health Administration

Construction

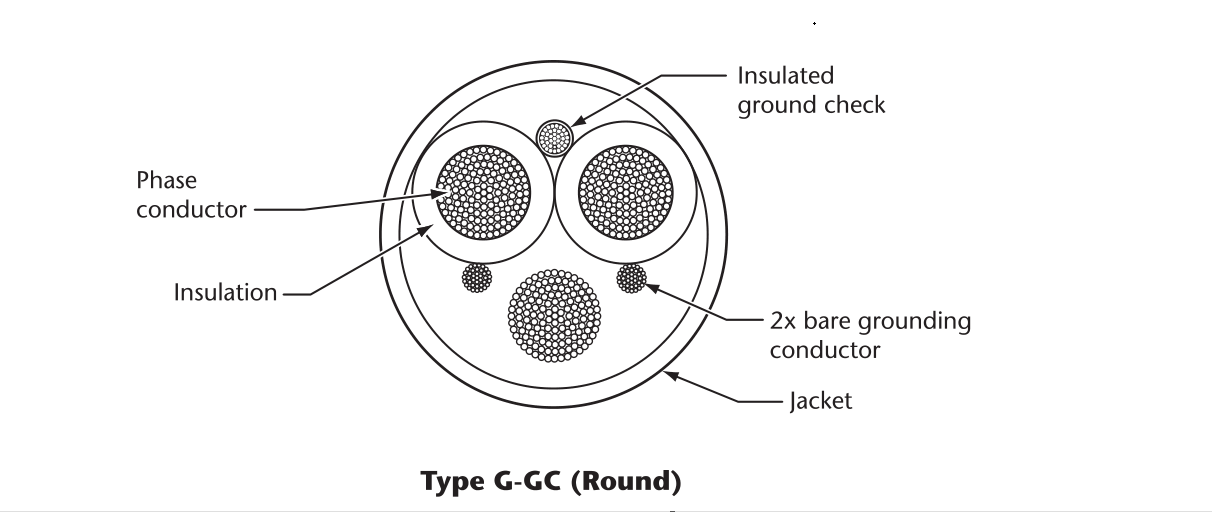

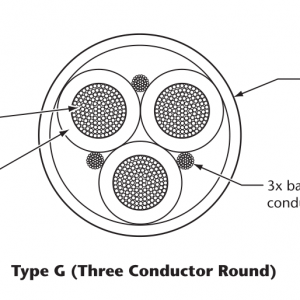

1. Power Conductor: Bare or tinned soft copper conductors

2. Separator: Polyester tape

3. Insulation: Ethylene Propylene Rubber (EPR), color coded for phase identification black, white, red

4. Ground Conductors: Bare or tinned soft copper conductors , may be uncovered, or covered which shall be green in color

The the covering may be in the form of an exruder layer, braid, tape or other suitable means.

5. Ground Check Conductor: Bare or tinned copper conductors with yellow Ethylene Propylene Rubber (EPR) insulation,

shall laid between the black and white power conductors

6. Inner Jacket: Black extra heavy-duty thermoset Chlorinated Polyethylene (CPE)

7. Reinforcement: Reinforcing twine applied between the two jacket layers

8. Outer Jacket: Extra heavy-duty thermoset Chlorinated Polyethylene (CPE), the jacket color can be orange, black or others.

Technical Parameter

| Power conductor | Each Grounding Conductor | Ground-check Conductor | Approx. Overall Diameter | |||||||

| Size | No. of Strands | Insulation Thickness | Size | Min.No. of strands | Size | Insulation Thickness | ||||

| mils | mm | AWG | AWG | mils | mm | In. | mm | |||

| 3x8AWG | 133 | 60 | 1.52 | 10 | 49 | 10 | 30 | 0.76 | 0.97 | 24.6 |

| 3x6AWG | 133 | 60 | 1.52 | 10 | 49 | 10 | 30 | 0.76 | 1.05 | 26.7 |

| 3x4AWG | 259 | 60 | 1.52 | 8 | 49 | 10 | 30 | 0.76 | 1.19 | 30.2 |

| 3x3AWG | 259 | 60 | 1.52 | 8 | 49 | 10 | 30 | 0.76 | 1.25 | 31.8 |

| 3x2AWG | 259 | 60 | 1.52 | 7 | 49 | 8 | 30 | 0.76 | 1.34 | 34.0 |

| 3x1AWG | 259 | 80 | 2.03 | 6 | 133 | 8 | 45 | 1.14 | 1.51 | 38.4 |

| 3×1/0AWG | 266 | 80 | 2.03 | 5 | 133 | 8 | 45 | 1.14 | 1.65 | 41.9 |

| 3×2/0AWG | 324 | 80 | 2.03 | 4 | 133 | 8 | 45 | 1.14 | 1.75 | 44.5 |

| 3×3/0AWG | 418 | 80 | 2.03 | 3 | 133 | 8 | 45 | 1.14 | 1.89 | 48.0 |

| 3×4/0AWG | 532 | 80 | 2.03 | 2 | 133 | 8 | 45 | 1.14 | 2.04 | 51.8 |

| 3x250MCM | 608 | 95 | 2.41 | 2 | 133 | 8 | 45 | 1.14 | 2.39 | 60.7 |

| 3x300MCM | 735 | 95 | 2.41 | 1 | 133 | 8 | 45 | 1.14 | 2.56 | 65.0 |

| 3x350MCM | 855 | 95 | 2.41 | 1/0 | 259 | 8 | 45 | 1.14 | 2.68 | 68.1 |

| 3x400MCM | 980 | 95 | 2.41 | 1/0 | 259 | 8 | 45 | 1.14 | 2.82 | 71.6 |

| 3x450MCM | 1127 | 95 | 2.41 | 2/0 | 259 | 8 | 45 | 1.14 | 2.94 | 74.7 |

| 3x500MCM | 1221 | 95 | 2.41 | 2/0 | 259 | 8 | 45 | 1.14 | 3.03 | 77.0 |

Note: From 4/0AWG to 500MCM, these cables require extra-heavy duty jackets.