Application

Portable power cable designed for normal or hard service use where maximum resistance to flex fatigueis required. Used in extremely demanding applications including trailing cable on mobile mining equipment, diesel electric locomotives, lifting magnets, cranes, cutters,loaders, conveyors, drills and pumps where grounded circuits are not required.

Temperature rating and voltage rating

90°C and 2000V

Standards reference

ASTM B3 Specification for Soft or Annealed Copper Wire

ASTM B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

ASTM B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Copper Conductors

ICEA S-75-381 Portable and Power Feeder Cables for Use In Mines and Similar Applications

Construction

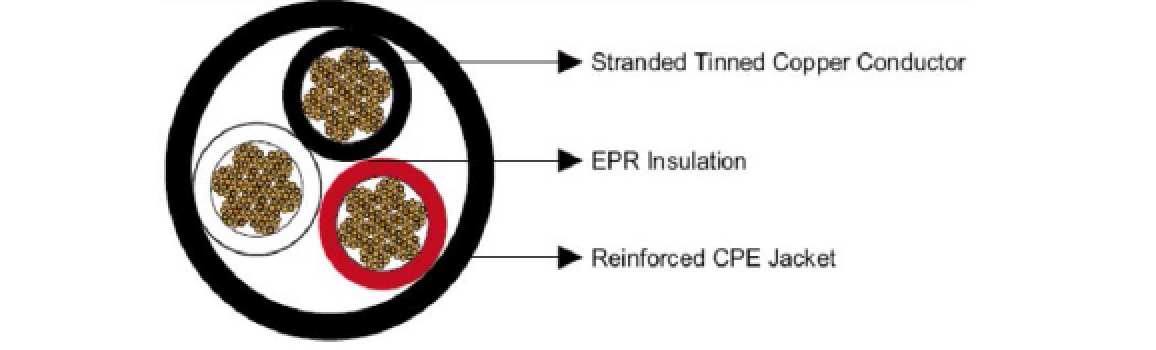

1. Power Conductor: Tinned copper or bare soft copper conductors from 8AWG to 1000kcmil

2. Separator: Polyester tape

3. Insulation: Ethylene Propylene Rubber (EPR)

Color Code as below

| Cond. # | Color |

| 2 | Black, White |

| 3 | Black, White, Green |

| 4 | Black, White, Red, Green |

| 5 | Black, White, Red, Green,Orange |

| 6 | Black, White, Red, Green,Orange, Blue |

4. Assembly:Multiple conductor constructions cabled with fillers for roundness (except single conductor)

5.Reinforcement binder: Reinforcing twine between the CPE jacket

6. Jacket: Thermosetting Chlorinated Polyethylene (CPE)

Technical Parameter

Single Conductor Round Portable Power Cable

| Size

AWG or kcmil |

EPR Insulation Thickness | Approx Cable OD | Test voltage | ||||

| mils | mm | Normal Service | Hard service | AC | |||

| In. | mm | In. | mm | Kv | |||

| 8 | 60 | 1.52 | 0.441 | 11.2 | 0.51 | 13.0 | 7.0 |

| 6 | 60 | 1.52 | 0.512 | 13.0 | 0.59 | 15.0 | 7.0 |

| 4 | 60 | 1.52 | 0.571 | 14.5 | 0.64 | 16.3 | 7.0 |

| 3 | 60 | 1.52 | 0.630 | 16.0 | 0.68 | 17.3 | 7.0 |

| 2 | 60 | 1.52 | 0.661 | 16.8 | 0.71 | 18.0 | 7.0 |

| 1 | 80 | 2.03 | 0.740 | 18.8 | 0.82 | 20.8 | 8.0 |

| 1/0 | 80 | 2.03 | 0.772 | 19.6 | 0.87 | 22.1 | 8.0 |

| 2/0 | 80 | 2.03 | 0.819 | 20.8 | 0.95 | 24.1 | 8.0 |

| 3/0 | 80 | 2.03 | 0.870 | 22.1 | 1.04 | 26.4 | 8.0 |

| 4/0 | 80 | 2.03 | 0.929 | 23.6 | 1.11 | 28.2 | 8.0 |

| 250 | 95 | 2.41 | 0.992 | 25.2 | 1.18 | 30.0 | 9.5 |

| 300 | 95 | 2.41 | 1.091 | 27.7 | 1.25 | 31.8 | 9.5 |

| 350 | 95 | 2.41 | 1.150 | 29.2 | 1.30 | 33.0 | 9.5 |

| 400 | 95 | 2.41 | 1.201 | 30.5 | 1.36 | 34.5 | 9.5 |

| 450 | 95 | 2.41 | 1.260 | 32.0 | 1.41 | 35.8 | 9.5 |

| 500 | 95 | 2.41 | 1.311 | 33.3 | 1.45 | 36.8 | 9.5 |

Two to Six Conductors Round Portable Power Cable

| Power conductor | Approx. Outside Diameter | Test Voltage Kv | |||||

| Size | Min. No. of wires | Insulation Thickness | |||||

| mils | mm | In. | mm | AC | DC | ||

| 2x8AWG | 49 | 60 | 1.52 | 0.81 | 20.6 | 7.0 | 21.0 |

| 2x6AWG | 49 | 60 | 1.52 | 0.93 | 23.6 | 7.0 | 21.0 |

| 2x4AWG | 49 | 60 | 1.52 | 1.08 | 27.4 | 7.0 | 21.0 |

| 2x3AWG | 49 | 60 | 1.52 | 1.17 | 29.7 | 7.0 | 21.0 |

| 2x2AWG | 133 | 60 | 1.52 | 1.27 | 32.3 | 7.0 | 21.0 |

| 2x1AWG | 133 | 80 | 2.03 | 1.44 | 36.6 | 8.0 | 24.0 |

| 2×1/0AWG | 133 | 80 | 2.03 | 1.52 | 38.6 | 8.0 | 24.0 |

| 2×2/0AWG | 133 | 80 | 2.03 | 1.65 | 41.9 | 8.0 | 24.0 |

| 2×3/0AWG | 259 | 80 | 2.03 | 1.77 | 45.0 | 8.0 | 24.0 |

| 2×4/0AWG | 259 | 80 | 2.03 | 1.92 | 48.8 | 8.0 | 24.0 |

| 2x250MCM | 259 | 95 | 2.41 | 2.1 | 53.3 | 9.5 | 28.5 |

| 2x300MCM | 259 | 95 | 2.41 | 2.22 | 56.4 | 9.5 | 28.5 |

| 2x350MCM | 259 | 95 | 2.41 | 2.36 | 59.9 | 9.5 | 28.5 |

| 2x400MCM | 259 | 95 | 2.41 | 2.47 | 62.7 | 9.5 | 28.5 |

| 2x450MCM | 259 | 95 | 2.41 | 2.6 | 66.0 | 9.5 | 28.5 |

| 2x500MCM | 259 | 95 | 2.41 | 2.7 | 68.6 | 9.5 | 28.5 |

| 3x8AWG | 49 | 60 | 1.52 | 0.91 | 23.1 | 7.0 | 21.0 |

| 3x6AWG | 49 | 60 | 1.52 | 1.01 | 25.7 | 7.0 | 21.0 |

| 3x4AWG | 49 | 60 | 1.52 | 1.17 | 29.7 | 7.0 | 21.0 |

| 3x3AWG | 49 | 60 | 1.52 | 1.24 | 31.5 | 7.0 | 21.0 |

| 3x2AWG | 133 | 60 | 1.52 | 1.34 | 34.0 | 7.0 | 21.0 |

| 3x1AWG | 133 | 80 | 2.03 | 1.51 | 38.4 | 8.0 | 24.0 |

| 3×1/0AWG | 133 | 80 | 2.03 | 1.65 | 41.9 | 8.0 | 24.0 |

| 3×2/0AWG | 133 | 80 | 2.03 | 1.75 | 44.5 | 8.0 | 24.0 |

| 3×3/0AWG | 259 | 80 | 2.03 | 1.89 | 48.0 | 8.0 | 24.0 |

| 3×4/0AWG | 259 | 80 | 2.03 | 2.04 | 51.8 | 8.0 | 24.0 |

| 3x250MCM | 259 | 95 | 2.41 | 2.39 | 60.7 | 9.5 | 28.5 |

| 3x300MCM | 259 | 95 | 2.41 | 2.56 | 65.0 | 9.5 | 28.5 |

| 3x350MCM | 259 | 95 | 2.41 | 2.68 | 68.1 | 9.5 | 28.5 |

| 3x400MCM | 259 | 95 | 2.41 | 2.82 | 71.6 | 9.5 | 28.5 |

| 3x450MCM | 259 | 95 | 2.41 | 2.94 | 74.7 | 9.5 | 28.5 |

| 3x500MCM | 259 | 95 | 2.41 | 3.03 | 77.0 | 9.5 | 28.5 |

| 4x8AWG | 49 | 60 | 1.52 | 0.99 | 25.1 | 7.0 | 21.0 |

| 4x6AWG | 49 | 60 | 1.52 | 1.1 | 27.9 | 7.0 | 21.0 |

| 4x4AWG | 49 | 60 | 1.52 | 1.27 | 32.3 | 7.0 | 21.0 |

| 4x3AWG | 49 | 60 | 1.52 | 1.34 | 34.0 | 7.0 | 21.0 |

| 4x2AWG | 133 | 60 | 1.52 | 1.48 | 37.6 | 7.0 | 21.0 |

| 4x1AWG | 133 | 80 | 2.03 | 1.68 | 42.7 | 8.0 | 24.0 |

| 4×1/0AWG | 133 | 80 | 2.03 | 1.79 | 45.5 | 8.0 | 24.0 |

| 4×2/0AWG | 133 | 80 | 2.03 | 1.93 | 49.0 | 8.0 | 24.0 |

| 4×3/0AWG | 259 | 80 | 2.03 | 2.07 | 52.6 | 8.0 | 24.0 |

| 4×4/0AWG | 259 | 80 | 2.03 | 2.26 | 57.4 | 8.0 | 24.0 |

| 4x250MCM | 259 | 95 | 2.41 | 2.66 | 67.6 | 9.5 | 28.5 |

| 4x300MCM | 259 | 95 | 2.41 | 2.84 | 72.1 | 9.5 | 28.5 |

| 4x350MCM | 259 | 95 | 2.41 | 2.98 | 75.7 | 9.5 | 28.5 |

| 4x400MCM | 259 | 95 | 2.41 | 3.14 | 79.8 | 9.5 | 28.5 |

| 4x450MCM | 259 | 95 | 2.41 | 3.26 | 82.8 | 9.5 | 28.5 |

| 4x500MCM | 259 | 95 | 2.41 | 3.40 | 86.4 | 9.5 | 28.5 |

| 5x8AWG | 49 | 60 | 1.52 | 1.07 | 27.2 | 7.0 | 21.0 |

| 5x6AWG | 49 | 60 | 1.52 | 1.21 | 30.7 | 7.0 | 21.0 |

| 5x4AWG | 49 | 60 | 1.52 | 1.40 | 35.6 | 7.0 | 21.0 |

| 5x3AWG | 49 | 60 | 1.52 | 1.48 | 37.6 | 7.0 | 21.0 |

| 5x2AWG | 133 | 60 | 1.52 | 1.61 | 40.9 | 7.0 | 21.0 |

| 5x1AWG | 133 | 80 | 2.03 | 1.88 | 47.8 | 8.0 | 24.0 |

| 6x8AWG | 49 | 60 | 1.52 | 1.18 | 30.0 | 7.0 | 21.0 |

| 6x6AWG | 49 | 60 | 1.52 | 1.31 | 33.3 | 7.0 | 21.0 |

| 6x4AWG | 49 | 60 | 1.52 | 1.52 | 38.6 | 7.0 | 21.0 |

| 6x3AWG | 49 | 60 | 1.52 | 1.61 | 40.9 | 7.0 | 21.0 |

| 6x2AWG | 133 | 60 | 1.52 | 1.75 | 44.5 | 7.0 | 21.0 |

| 6x1AWG | 133 | 80 | 2.03 | 2.05 | 52.1 | 8.0 | 24.0 |