Power Cables, 600/1000V

Application

These cables are used for electricity supply in low voltage installation system, They are suitable for installation in indoors and outdoors, in cable ducts, under ground, in power and switching stations, local energy distributions, industrial plants.

Standard

IEC60502-1-IEC60502-1: Power cables with extruded insulation for rated voltages of 1 kV ((Um = 1,2 kV) and 3 kV (Um = 3,6 kV)

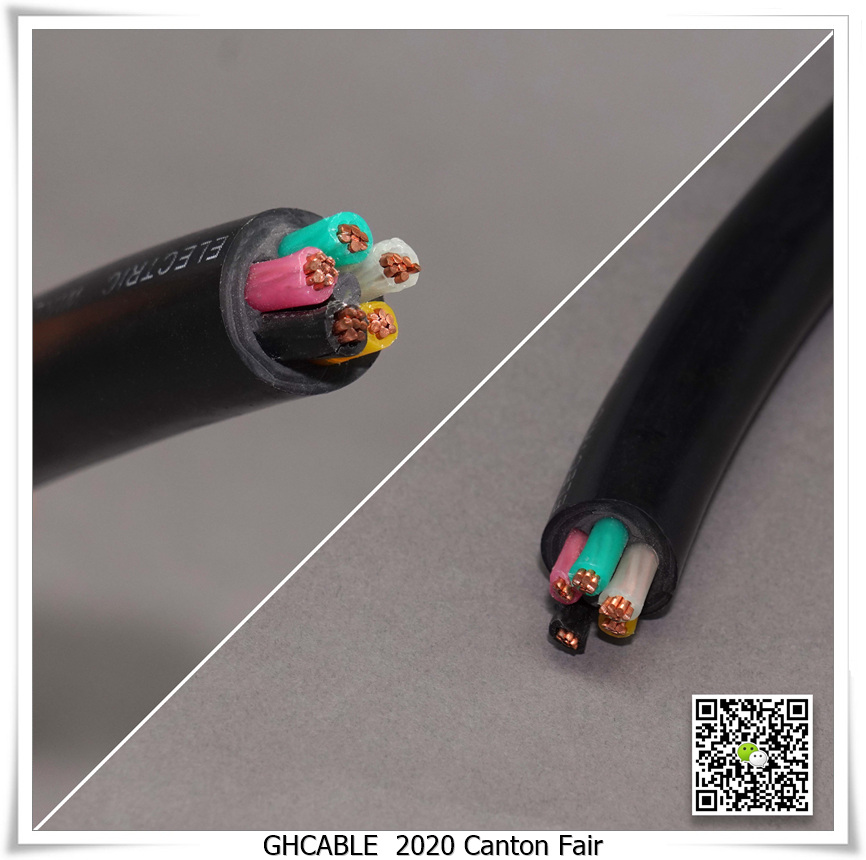

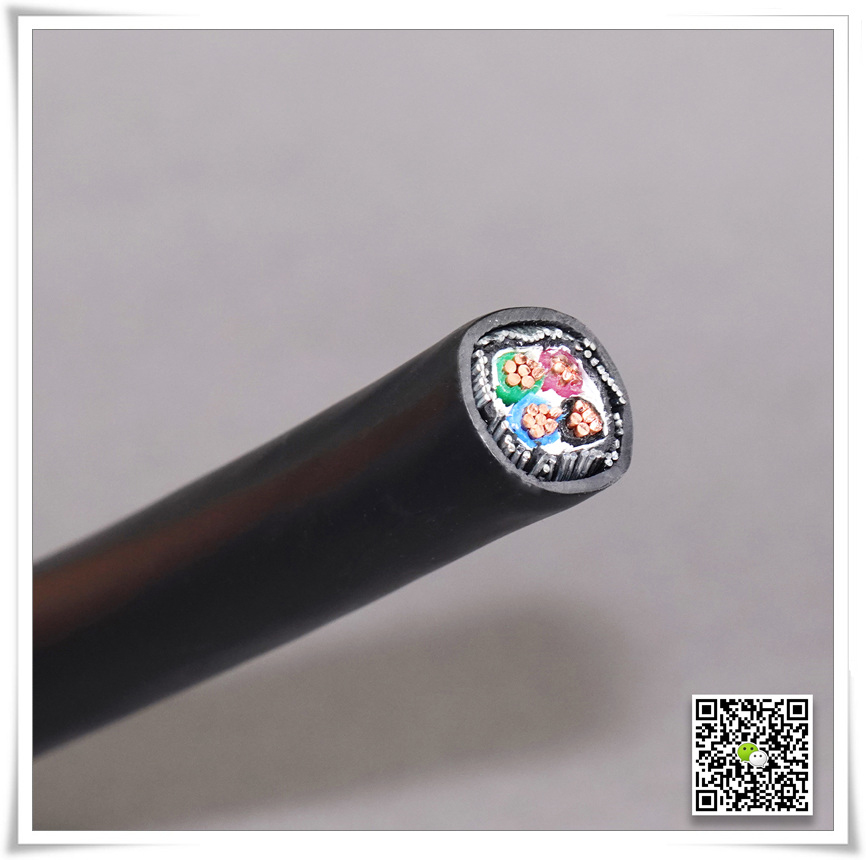

Construction

Conductor: Class 1 or Class 2 of plain or metal-coated annealed copper, or of plain aluminium or aluminium alloy, or Class 5 of plain or metal-coated copper in accordance with IEC 60228

Insulation: PVC or XLPE or EPR

Colour Code Colour Code (1) :

1 Core : Red or Black

2 Cores : Red, Black

3 Cores : Red, Yellow, Blue

4 Cores : Red, Yellow, Blue, Black

5 Cores : Red, Yellow, Blue, Black, Green

Above 5 Cores: Black Cores with White numerals

Colour Code (2) :

1 Core : Brown or Blue

2 Cores : Brown, Blue

3 Cores : Brown, Black, Grey

4 Cores : Blue, Brown, Black, Grey

5 Cores : Green/Yellow, Blue, Brown, Black, Grey

Above 5 Cores: Black Cores with White numerals

Other colours can be manufactured upon request.

Assembly

Binder: A suitable binder is permitted before application of an extruded inner covering

Innner covering and filler: Innner covering may be extruded or lapped.

The materials used for inner coverings and fillers shall be suitable for the operating temperature of the cable and compatible with the insulating material

For halogen free cables, the inner covering and fillers shall also be halogen free compound.

Armor : armour aluminum/galvanized steel/steel wires applied helically over the inner covering or double aluminum/steel tapes and copper/tinned copper wire,can also be manufactured upon request.

Outer Sheath: extruded PVC Type ST1/ST, (or Polyethylene type ST3/ST7; or Halogen free compound ST8; or Polychloroprene, chlorosulfonated polyethylene or similar polymers, type SE1)

Technical Characteristics

Rated voltage: 600/1000V

Test voltage: 3500V

Take PVC Insulated (PVC Sheathed) Power Cable (Unarmored) for example

| No. od cores x Nom. Cross-section | Nom. insulation thickness | Nom. sheath thickness | Approx OD of cable |

| mm2 | mm | mm | mm |

| 1 x 1.5 | 0.8 | 1.4 | 6.0 |

| 1 x 2.5 | 0.8 | 1.4 | 6.4 |

| 1 x 4 | 1.0 | 1.4 | 7.4 |

| 1 x 6 | 1.0 | 1.4 | 7.9 |

| 1 x 10 | 1.0 | 1.4 | 8.7 |

| 1 x 16 | 1.0 | 1.4 | 9.6 |

| 1 x 25 | 1.2 | 1.4 | 11.1 |

| 1 x 35 | 1.2 | 1.4 | 12.2 |

| 1 x 50 | 1.4 | 1.4 | 14.0 |

| 1 x 70 | 1.4 | 1.5 | 15.6 |

| 1 x 95 | 1.6 | 1.5 | 17.6 |

| 1 x 120 | 1.6 | 1.6 | 19.2 |

| 1 x 150 | 1.8 | 1.7 | 21.2 |

| 1 x 185 | 2.0 | 1.7 | 23.1 |

| 1 x 240 | 2.2 | 1.8 | 25.9 |

| 1 x 300 | 2.4 | 1.9 | 28.5 |

| 2 x 1.5 | 0.8 | 1.8 | 10.2 |

| 2 x 2.5 | 0.8 | 1.8 | 11.0 |

| 2 x 4 | 1.0 | 1.8 | 12.8 |

| 2 x 6 | 1.0 | 1.8 | 13.8 |

| 2 x 10 | 1.0 | 1.8 | 15.4 |

| 2 x 16 | 1.0 | 1.8 | 17.2 |

| 2 x 25 | 1.2 | 1.8 | 20.2 |

| 2 x 35 | 1.2 | 1.8 | 22.4 |

| 2 x 50 | 1.4 | 1.8 | 25.8 |

| 2 x 70 | 1.4 | 1.9 | 28.8 |

| 2 x 95 | 1.6 | 2.0 | 33.0 |

| 2 x 120 | 1.6 | 2.1 | 36.0 |

| 2 x 150 | 1.8 | 2.2 | 39.8 |

| 2 x 185 | 2.0 | 2.4 | 44.0 |

| 2 x 240 | 2.2 | 2.6 | 49.6 |

| 3 x 1.5 | 0.8 | 1.8 | 10.7 |

| 3 x 2.5 | 0.8 | 1.8 | 11.5 |

| 3 x 4 | 1.0 | 1.8 | 13.5 |

| 3 x 6 | 1.0 | 1.8 | 14.6 |

| 3 x 10 | 1.0 | 1.8 | 16.3 |

| 3 x 16 | 1.0 | 1.8 | 18.2 |

| 3 x 25 | 1.2 | 1.8 | 21.5 |

| 3 x 35 | 1.2 | 1.8 | 23.9 |

| 3 x 50 | 1.4 | 1.8 | 27.5 |

| 3 x 70 | 1.4 | 1.9 | 30.8 |

| 3 x 95 | 1.6 | 2.1 | 35.5 |

| 3 x 120 | 1.6 | 2.2 | 38.7 |

| 3 x 150 | 1.8 | 2.4 | 43.0 |

| 3 x 185 | 2.0 | 2.5 | 47.3 |

| 3 x 240 | 2.2 | 2.7 | 53.3 |

| 4 x 4 | 1 | 1.8 | 14.6 |

| 4 x 6 | 1 | 1.8 | 15.8 |

| 4 x 10 | 1 | 1.8 | 17.8 |

| 4 x 16 | 1 | 1.8 | 19.9 |

| 4 x 25 | 1.2 | 1.8 | 23.6 |

| 4 x 35 | 1.2 | 1.8 | 26.2 |

| 4 x 50 | 1.4 | 1.9 | 30.5 |

| 4 x 70 | 1.4 | 2.1 | 34.3 |

| 4 x 95 | 1.6 | 2.2 | 39.4 |

| 4 x 120 | 1.6 | 2.3 | 43.0 |

| 4 x 150 | 1.8 | 2.5 | 47.7 |

| 4 x 185 | 2.0 | 2.7 | 52.7 |

| 4 x 240 | 2.2 | 2.8 | 59.2 |