Introduction

GHCABLE offers a wide selection of UL-listed 600V Tray Cable for a variety of control and power applications.

Multi-conductor versions are available as standards from 18AWG to 500MCM. These are unshielded and

shielded versions that come with various insulation and jacket combinations.

Application

These cables are suitable for installation in wet or dry locations. The cables can be used in outdoor and

direct burial applications, and without conduit (exposed runs). TC cable is designed for use in all electrical

equipment.Wind turbine power and control cable /WTTC is intended to be installed in cable trays or raceways

within a wind turbine generator.

Temperature rating and voltage rating

TC: 90°C, 600V

WTTC: 90°C 1000V

Standards

UL1277 for TC, TCER ; UL listed file No. E353915

UL 2277 for WTTC ; UL listed file No. E354502

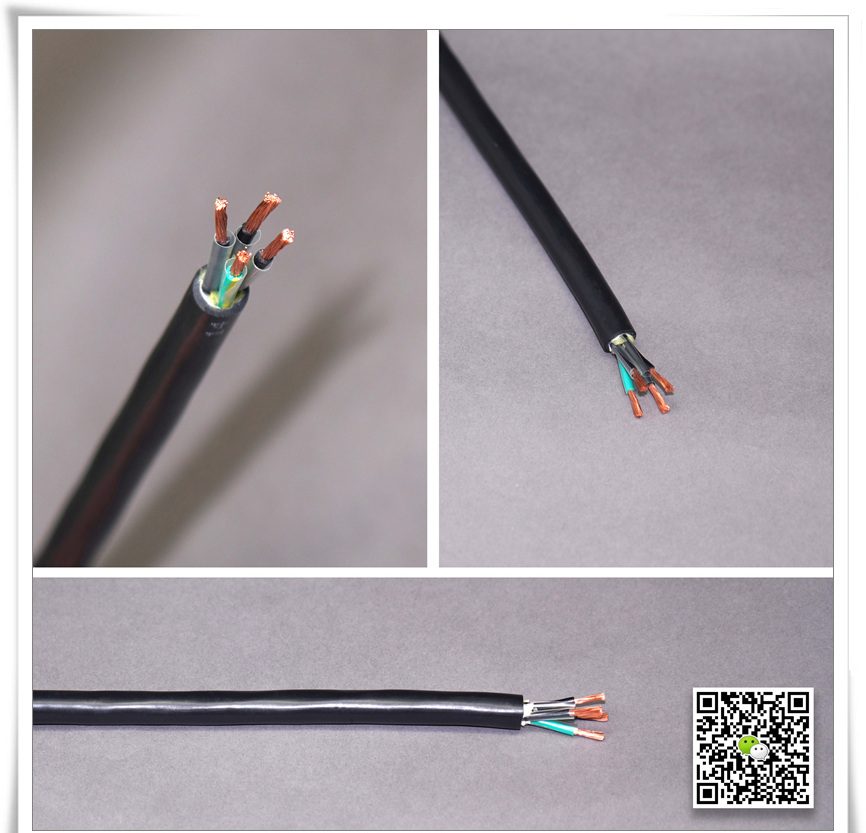

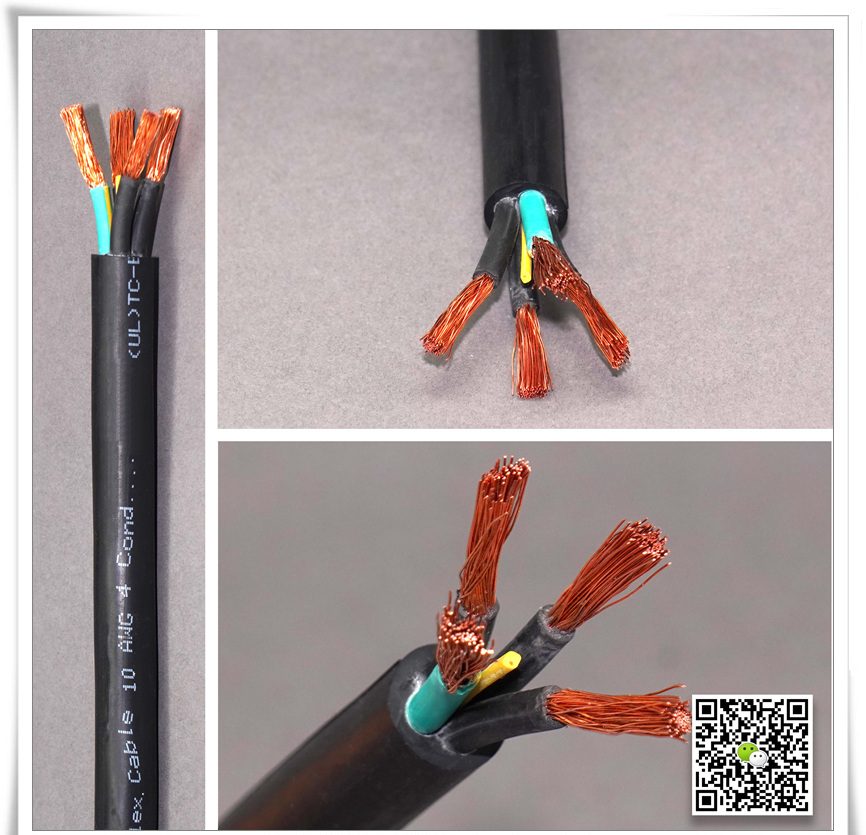

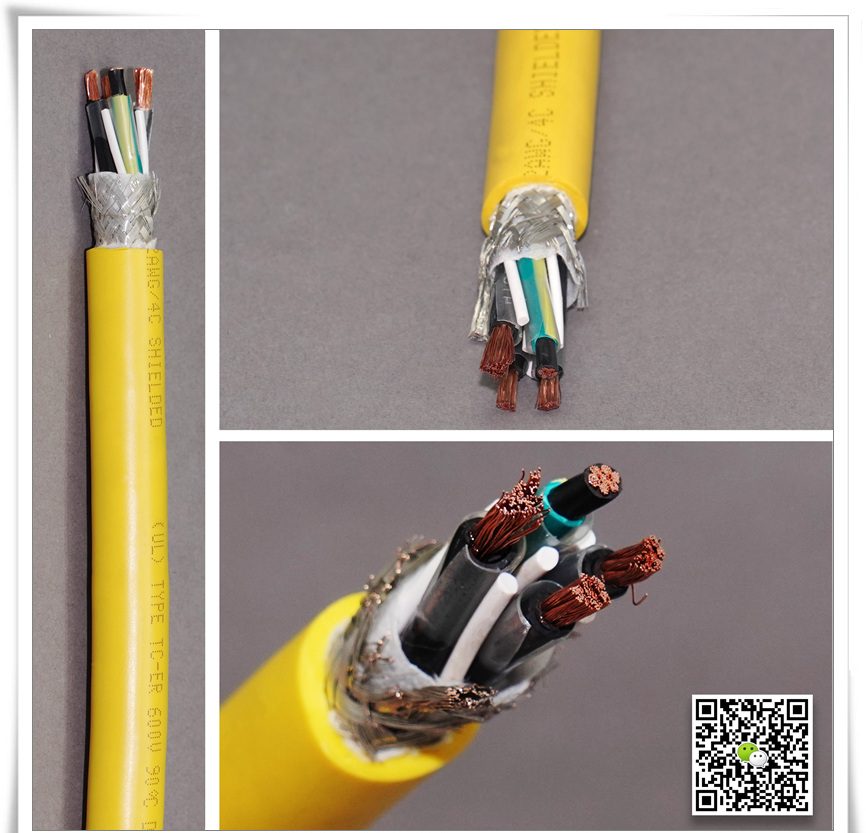

Construction

Soft annealed bare or tinned copper conductors, with various insulation and jacket options.

Conductor: Soft annealed bare or tinned copper conductors

Insulation: Polyvinyl chloride (PVC) with nylon jacketed (THHN or THWN,TFN or TFFN), PVC (THHW), or XLPE(XHHW) or EPR

Color code: Black conductor with consecutive white numbers; green-yellow earth wire from 3 conductors

Separator: Non-woven tape

Jacket: Sunlight and oil resistant PVC or CPE

Take the soft flexible copper conductor, PVC/Nylon insulation, PVC jacket for example

| Size | Conductor Strand (#/AWG) | PVC Insulation Thickness | Nylon Jacket Thickness | PVC Jacket Thickness | Approx. Overall Diameter | Approx. Net Weight | |||||

| AWG or MCM | mm | mils | mm | mils | mm | mils | mm | inch | kg/km | lbs/1000ft | |

| 3*18AWG | 19/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 7.9 | 0.311 | 84 | 56 |

| 4*18AWG | 19/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 8.4 | 0.331 | 101 | 68 |

| 5*18AWG | 19/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 9.1 | 0.358 | 127 | 85 |

| 3*16AWG | 26/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 8.6 | 0.339 | 102 | 69 |

| 4*16AWG | 26/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 9.3 | 0.365 | 126 | 85 |

| 5*16AWG | 26/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 9.8 | 0.386 | 151 | 101 |

| 3*14AWG | 41/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 9.8 | 0.384 | 131 | 88 |

| 4*14AWG | 41/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 10.0 | 0.394 | 162 | 109 |

| 5*14AWG | 41/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 11.1 | 0.437 | 196 | 132 |

| 3*12AWG | 65/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 10.6 | 0.417 | 176 | 118 |

| 4*12AWG | 65/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 11.5 | 0.452 | 223 | 150 |

| 5*12AWG | 65/30 | 0.38 | 15 | 0.10 | 4 | 1.14 | 45 | 12.7 | 0.500 | 271 | 182 |

| 3*10AWG | 105/30 | 0.51 | 20 | 0.10 | 4 | 1.14 | 45 | 12.5 | 0.492 | 261 | 175 |

| 4*10AWG | 105/30 | 0.51 | 20 | 0.10 | 4 | 1.52 | 60 | 14.6 | 0.576 | 362 | 243 |

| 5*10AWG | 105/30 | 0.51 | 20 | 0.10 | 4 | 1.52 | 60 | 15.7 | 0.619 | 453 | 304 |

| 3*8AWG | 168/30 | 0.76 | 30 | 0.13 | 5 | 1.52 | 60 | 17.4 | 0.686 | 506 | 340 |

| 4*8AWG | 168/30 | 0.76 | 30 | 0.13 | 5 | 1.52 | 60 | 19.2 | 0.756 | 644 | 433 |

| 5*8AWG | 168/30 | 0.76 | 30 | 0.13 | 5 | 1.52 | 60 | 20.9 | 0.824 | 788 | 529 |