Application

General purpose building wire for services feeders and branch circuits. Also used for wiring of machine tools (stranded), appliances, and control circuits

Temperature rating and voltage rating:

90℃ dry / 75℃ wet, 600V.

Standards

PNS35-1

Construction

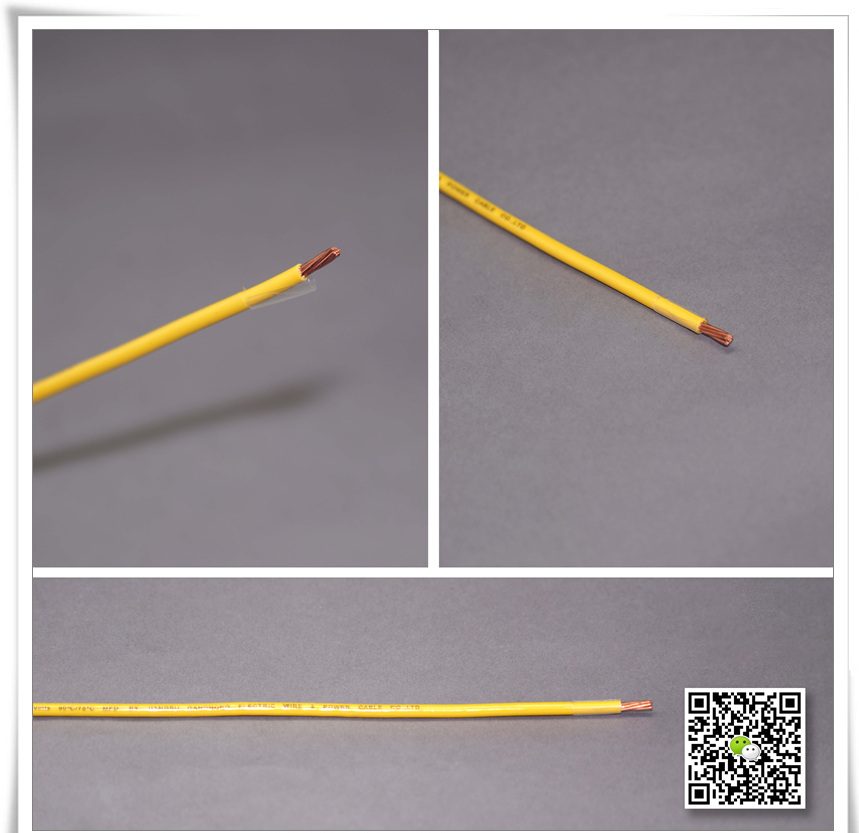

Conductor

Conductor

Annealed copper wire

- Conforming to requirements of PNS 260 for solid conductor or

- PNS 1207 for stranded conductors

Insulation

PVC conforming to the requirements of PNS 661

Available colors are red, white, blue, green, black, etc.

Jacket:Tough polyamide (Nylon)

Package type :Common coil, reel, gift box, or can do upon request.

General data for type THHN/THWN, 90℃ Dry/75℃ Wet, 600V wire

| Conductor | Minimum insulation thickness, mm |

Minimum nylon thickness mm |

Approx. overall diameter mm |

Test voltage, KV a.c. |

Minimum insulation resistance, MΩ-km |

|||||||||

| Nominal sectional area mm2 |

Composition | Outside diameter mm |

||||||||||||

| Number of wires |

Wire diameter mm |

|||||||||||||

| Average | At any point |

Spark | Immersion | 20℃ | 60℃ | 75℃ | ||||||||

| THWN | THHN | THWN | THHN | THWN | THHN | |||||||||

| 2.0 | 1 | 1.6 | 1.60 | 0.40 | 0.34 | 0.10 | 2.60 | 7.5 | 2.0 | 2.0 | 130 | 130 | 0.05 | 0.05 |

| 7 | 0.6 | 1.80 | 2.80 | |||||||||||

| 3.5 | 1 | 2.0 | 2.00 | 0.40 | 0.34 | 0.10 | 3.00 | 7.5 | 2.0 | 2.0 | 120 | 120 | 0.05 | 0.05 |

| 7 | 0.8 | 2.40 | 3.40 | |||||||||||

| 5.5 | 1 | 2.6 | 2.60 | 0.50 | 0.34 | 0.10 | 3.80 | 7.5 | 2.0 | 2.0 | 120 | 120 | 0.05 | 0.05 |

| 7 | 1.0 | 3.00 | 4.20 | |||||||||||

| 8.0 | 1 | 3.2 | 3.20 | 0.80 | 0.68 | 0.13 | 5.06 | 10.0 | 2.0 | 2.0 | 120 | 120 | 0.05 | 0.05 |

| 7 | 1.2 | 3.60 | 5.46 | |||||||||||

| 14 | 7 | 1.6 | 4.80 | 0.80 | 0.68 | 0.13 | 6.66 | 10.0 | 2.0 | 2.0 | 100 | 100 | 0.04 | 0.04 |

| 22 | 7 | 2.0 | 6.00 | 1.00 | 0.85 | 0.15 | 8.30 | 10.0 | 2.0 | 2.0 | 100 | 100 | 0.04 | 0.04 |

| 30 | 7 | 2.3 | 6.90 | 1.00 | 0.85 | 0.15 | 9.20 | 10.0 | 2.0 | 2.0 | 100 | 100 | 0.04 | 0.04 |

| 38 | 19 | 1.6 | 8.00 | 1.30 | 1.11 | 0.18 | 10.96 | 12.5 | 2.5 | 2.5 | 100 | 100 | 0.04 | 0.04 |

| 50 | 19 | 1.8 | 9.00 | 1.30 | 1.11 | 0.18 | 11.96 | 12.5 | 2.5 | 2.5 | 100 | 100 | 0.04 | 0.04 |

| 60 | 19 | 2 | 10.00 | 1.30 | 1.11 | 0.18 | 12.96 | 12.5 | 2.5 | 2.5 | 80 | 80 | 0.03 | 0.03 |

| 80 | 19 | 2.3 | 11.50 | 1.30 | 1.11 | 0.18 | 14.46 | 12.5 | 2.5 | 2.5 | 80 | 80 | 0.03 | 0.03 |

| 100 | 19 | 2.6 | 13.00 | 1.30 | 1.11 | 0.18 | 15.96 | 12.5 | 2.5 | 2.5 | 80 | 80 | 0.03 | 0.03 |

| 125 | 37 | 2.1 | 14.70 | 1.60 | 1.36 | 0.18 | 18.26 | 15.0 | 3.0 | 3.0 | 80 | 80 | 0.03 | 0.03 |

| 150 | 37 | 2.3 | 16.10 | 1.60 | 1.36 | 0.20 | 19.70 | 15.0 | 3.0 | 3.0 | 80 | 80 | 0.02 | 0.03 |

| 175 | 37 | 2.47 | 17.30 | 1.60 | 1.36 | 0.20 | 20.90 | 15.0 | 3.0 | 3.0 | 60 | 80 | 0.02 | 0.02 |

| 200 | 37 | 2.6 | 18.20 | 1.60 | 1.36 | 0.20 | 21.80 | 15.0 | 3.0 | 3.0 | 60 | 60 | 0.02 | 0.02 |

| 250 | 37 | 2.95 | 20.65 | 1.60 | 1.36 | 0.20 | 24.25 | 15.0 | 3.0 | 3.0 | 60 | 60 | 0.02 | 0.02 |

| 250 | 61 | 2.3 | 20.70 | 24.30 | ||||||||||

| 300 | 61 | 2.52 | 22.70 | 1.80 | 1.53 | 0.23 | 26.76 | 17.5 | 3.0 | 3.5 | 60 | 60 | 0.02 | 0.02 |

| 325 | 61 | 2.6 | 23.40 | 1.80 | 1.53 | 0.23 | 27.46 | 17.5 | 3.0 | 3.5 | 60 | 60 | 0.02 | 0.02 |

| 375 | 61 | 2.82 | 25.30 | 1.80 | 1.53 | 0.23 | 29.36 | 17.5 | 3.0 | 3.5 | 60 | 60 | 0.02 | 0.02 |

| 400 | 61 | 2.9 | 26.10 | 1.80 | 1.53 | 0.23 | 30.16 | 17.5 | 3.5 | 3.5 | 60 | 60 | 0.02 | 0.02 |

| 500 | 61 | 3.2 | 28.80 | 1.80 | 1.53 | 0.23 | 32.86 | 17.5 | 3.5 | 3.5 | 60 | 60 | 0.02 | 0.02 |